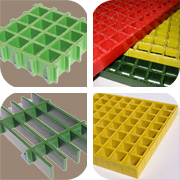

Molded Grating Process

Molded

grating is manufactured by our skilled worker through manual hand lay-up

in an open, heated steel mold. Continuous fiberglass roving is laid in

the mold in alternating layers and thoroughly wetted out with vinyl ester

or polyester resin. Molded

grating is manufactured by our skilled worker through manual hand lay-up

in an open, heated steel mold. Continuous fiberglass roving is laid in

the mold in alternating layers and thoroughly wetted out with vinyl ester

or polyester resin.

This continuous process constructs a one piece panel that offers excellent

corrosion resistance and bidirectional strength in both bearing and cross

bars. This process involves constant monitoring of temperature control

and curing cycle.

When the panel naturally cured, the surface shall have a concave surface

for slip resistance. A standard grit surface is made through a secondary

operation by bonding grit to the grating panel. If the grating is to have

embedded grit, the grit shall be applied during the curing cycle before

the panel ejected from the mold.

|